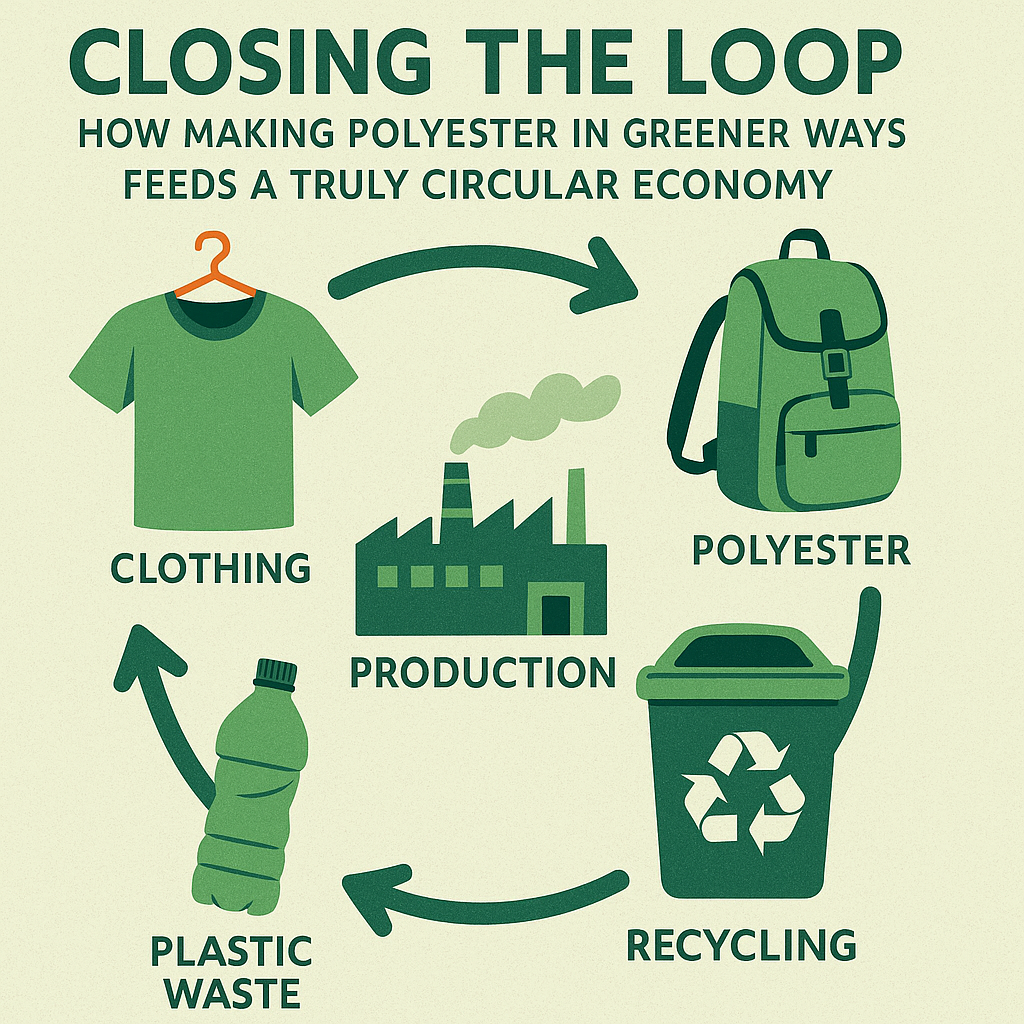

With the escalating issues surrounding plastic waste, the processes of recycling are critical for lessening ecological effects while endorsing a circular economy. One of the types of plastics that is frequently regarded with worry is the rPET flakes which have high quality and are white. They are of significant importance to consider the efficiency and sustainability of the recycling process. Why are these flakes important, and what can manufacturers and recyclers do to give them priority?

What are White rPET Flakes?

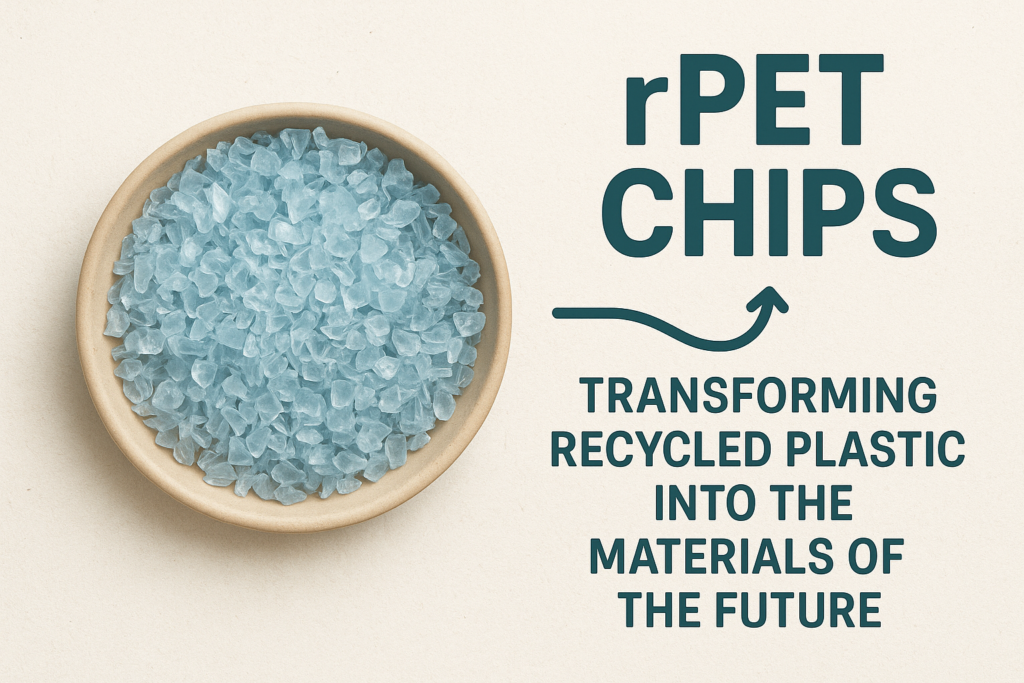

White rPET flakes are made from post-consumer plastics like bottles and containers. The plastics are first gathered, separated, sanitized, and then fragmented into fine flakes. These high-quality white rPET flakes are a result of the advanced stage of recycling when the flakes are rendered to their cleanest state, free from any sort of contamination coupled with a neutral state suitable for processing into sturdy raw materials.

The Importance of High-Quality White rPET Flakes in Production

The Role of High-Quality White rPET Flakes In Production Processes. The sectors of packaging, textiles, automotive, and even consumer goods show growing interest in the use of white rPET flakes. These are some of the explanations provided:

- Improved Product Prototype Design: White rPET flakes, being of higher grade, are generally accepted for food-grade applications because a higher level of cleanliness and purity is required. The more these high-grade flakes are used the greater the chances that the recycled material is actually in good condition. Low-grade contamination flakes lead to unsightly colors and high-grade rPET flakes help in getting clean Clear Cup Blends.

- Flexibility: White rPET flakes can be processed to make clear and lightly colored products without further need for dyes…Because of their neutral color, manufacturers can achieve various aesthetic results.

- Lower Environmental Impact: There is a much lower emission of greenhouse gasses as well as energy spending when using rPET plastics as opposed to virgin ones. rPET flakes being of high-quality white rPET bypass the unsightly color rPET waste. These benefits can be Maximized considering longer lifecycle of the recycled materials.

- Production reliability: High-quality flakes enable producers to achieve reliable production standards. Unfortunately, low-quality flakes or contaminated flakes suffer from production inefficiencies, defects, and unsightly color variation in the final product.

The Importance of Quality When It Comes to rPET Flakes

While rPET flakes can be created from recycling facilities, their quality differs significantly. The distinction between low-grade and high-grade white rPET flakes comes down to the care given during the washing and sorting as well as the overall processing stages.

- Purity: As is typical for all rPET flakes, their quality is correlated with the amount of contamination in the product, such as paper, adhesive, and other plastic scraps. Premium rPET flakes have a high degree of purity with low levels of contamination.

- Low Moisture Content: Excess moisture greatly affects the performance of processing machinery while also weakening the strength and beauty of the final product. Premium rPET flakes are packaged with minimal moisture content, which prevents damage to the product.

- Uniform Flake Size: Uniform flake sizes also enhance the speed of manufacturing lines aside from melting consistency.

Additions of High-Quality White rPET Flakes

- Bottles for Beverages: The production of new bottles, especially clear and lightly colored ones, is a popular use of rPET. Because white flakes are clean and neutral, they are ideal to be used.

- Food Containers: White rPET flakes that meet food-grade standards are highly sought after for packaging films, as well as containers and trays.

- Textiles and Fibers: Clothes, upholstery, and industrial fabrics made from recycled polyester fibers are popular items made from rPET flakes.

- Filaments for 3D Printing: With the expansion of the 3D printing industry comes an increased need for sustainable filament. White rPET flakes can be transformed into eco-friendly 3D printing materials.

Also Read: RPSF the next innovative approach to sustainable fiber

Conclusion

The role of superior grade white rPET flakes in the plastic recycling industry is of paramount importance. They serve as building blocks for various industries to create sustainable, dependable, and visually acceptable recycled goods. Focusing on quality helps manufacturers not only enhance product performance but also make a positive difference in the environment.

Accomplishing sustainability and efficiency goals becomes easier when R and D focus on investing or procuring high grade white rPET flakes which supersede their business objectives while being environmentally conscious.