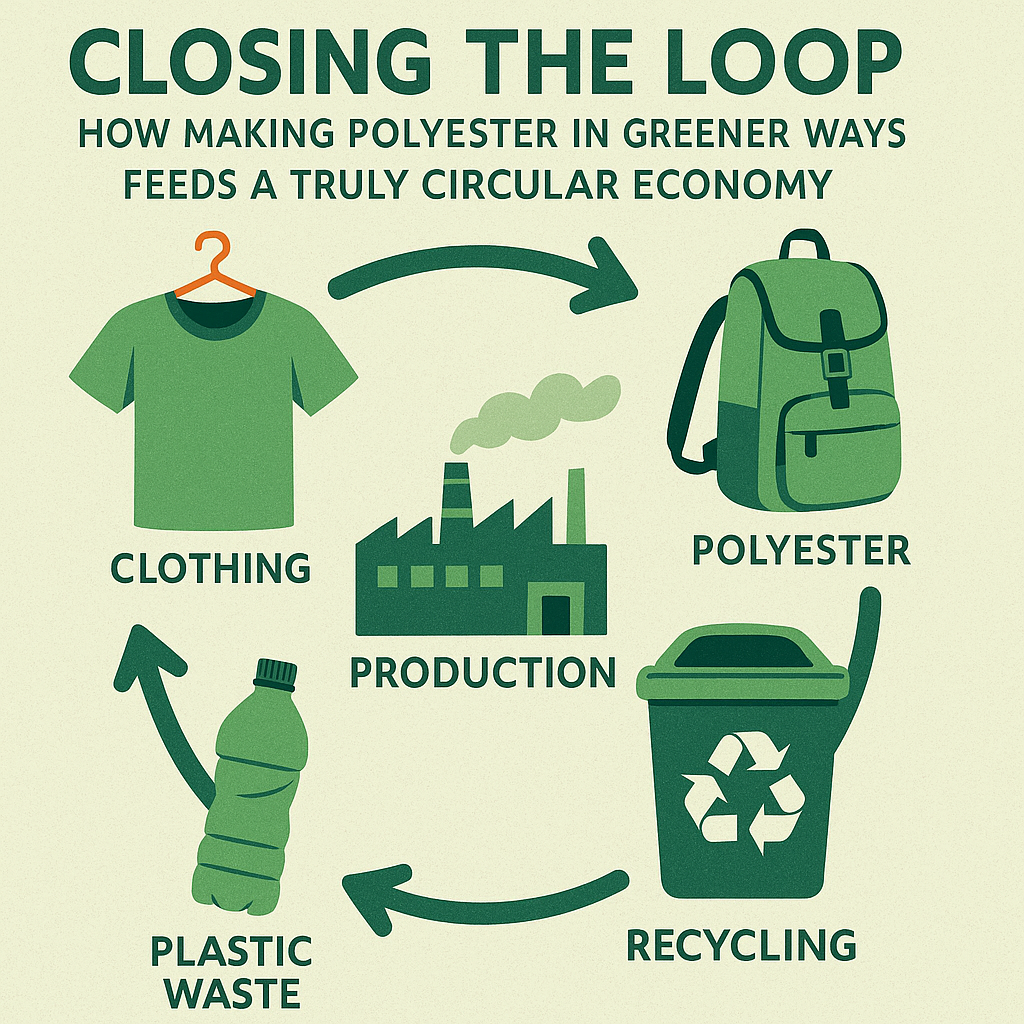

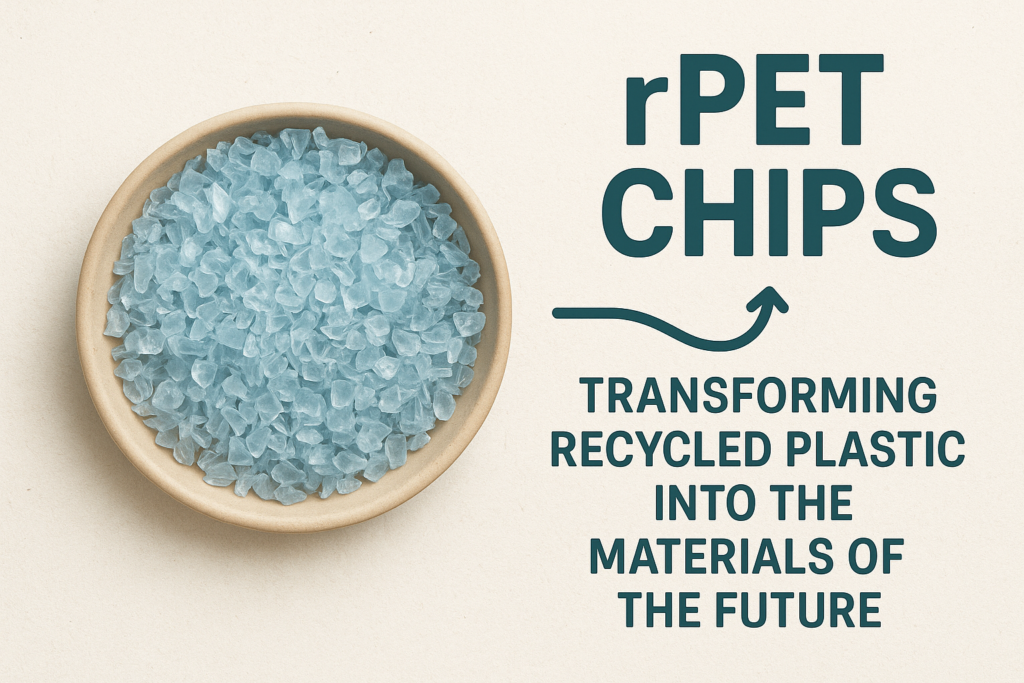

The word ‘sustainability’ in itself is no longer just a trend but rather something absolutely necessary in the world of modern textile and fashion. Designers have long considered RPSF-the versatility in form, eco-friendliness, and compatibility as fitting it perfectly into their line of endeavors and commitment to lowering impacts in the environment. An ideal alternative to virgin polyester and a key to attaining circular economy, RPSF, made from recycled PET bottles.

This hands-on guide will walk you through the process of implementing RPSF in your textile designs, from the sourcing of materials to its application, all while upholding the integrity of your design.

Knowing the Basics of RPSF

Before showing how to apply RPSF into textiles, let’s know first what makes this material special:

Sustainability: RPSF is sourced from post-consumer plastic bottles, thus eliminating waste and reducing the demand for virgin raw materials.

Versatility: It can be used alone or blended with other fibers. This offers flexibility for various applications.

Performance: RPSF retains most of the virgin polyester’s properties, including durability, moisture resistance, and easy dyeability.

Step 1: Source High-Quality RPSF

The first step in incorporating RPSF into your textiles is to source high-quality RPSF suppliers. In sourcing RPSF:

Check Certifications: Ensure that the suppliers are certified under Global Recycled Standard (GRS) to ensure that the material is sustainable and of quality.

Assess Quality: The fibers should be uniform in thickness, strength, and color compatibility to meet your design requirements.

Understand Customization Options: Most manufacturers offer RPSF in various deniers, lengths, and finishes to suit specific textile applications.

Step 2: Mix RPSF with Other Fibers

Though RPSF can be used independently, it can be blended with cotton, wool, or spandex to add more functionality and aesthetic appeal to your fabrics.

For Durability: Blend RPSF with cotton for strong yet breathable fabrics ideal for casual wear.

For Elasticity: Blend with spandex to create stretchable textiles suitable for sportswear and athleisure.

For Softness: Blend with viscose or bamboo fibers for softer, richer texture in home furnishings or premium fashion apparel.

Experiment with different blends to achieve the desired balance between performance and aesthetics.

Step 3: Use RPSF in Design End

RPSF offers a lot of scope for creative applications in textiles:

Apparel Design

RPSF is suited for making garments that are supposed to be durable and comfortable, such as:

Activewear: Its moisture-wicking properties make it a very good fabric for sportswear.

Apparel: RPSF is in great demand to be used for lightweight layers such as jackets and coats.

Ready-to-Wear: Offer fashionable and eco-friendly, casual wear.

Home Textile

Recycled polyester staple fiber is widely used to manufacture upholstery, cushions and even curtains. It is strong and hence, the finished products do not shrink and lose their texture.

Technical Textiles

The strength with versatility of RPSF makes it a good contender for industrial applications like Automotive Seat Covers and Geotextiles.

Step 4: Finalize Fabric Production

When working with RPSF, you will need to make adjustments in your production processes as follows:

Spinning: The fibers should be spun into yarns that have the correct twist and strength for the type of fabric you are trying to make.

Weaving/Knitting: RPSF can be easily integrated into the weaving and knitting processes. This gives a good degree of flexibility in the construction of the fabric.

Dyeing and Finishing: The dye affinity of RPSF (recycled polyester staple fiber) is similar to virgin polyester. This provides bright and lasting colors. Use eco-friendly dyes to make your textiles more sustainable.

Step 5: Communicate Sustainability to Consumers

Once you’ve successfully incorporated RPSF into your textiles, it’s crucial to communicate its benefits to your target audience. Consumers today value transparency and sustainability in the products they purchase.

Labeling: Emphasize the use of RPSF and its environmental advantages on product labels or packaging.

Marketing: Promote your sustainable approach through social media, blogs, or advertising campaigns.

Certifications: Display relevant certifications such as GRS to win the trust and confidence of the environmentally conscious customers.

Step 6: Stay Innovative

The use of recycled polyester staple fiber in textiles is always changing because of improvement in technology and design techniques. To be ahead of the game and think ahead:

Collaborate with Suppliers: Work collaboratively with RPSF producers to be abreast with the latest developments.

Research New Techniques: Be inventive to develop novel patterns and finishes using recycled polyester staple fiber.

Practice Circular Design Principles : Use recyclability as design element: consider easy disassembly that results in easier reprocessing by enabling it at the End-Life of the product

Benefits of Using RPSF

The following are just but few of the benefits provided upon utilization of RPSF.

Minimization of plastic waste thereby providing enough resources.

Cost-Effectiveness: The energy and raw materials used are lower than in the traditional production.

Market Appeal: It meets the growing demand of customers for environmentally friendly products.

Also Read: How Many Industries can one fibre impact rpsf

Conclusion

One way to assume environmental responsibility is integrating recycled polyester staple fiber into fabrics. It allows the designers a good chance of innovativeness as well as giving meaningfulness to the product by understanding the material and having access to high-quality fibers with a lot of versatility in application.

As the fashion industry becomes more eco-friendly, RPSF (recycled polyester staple fiber) is a great medium for designers who want to inspire the planet in the process of producing top-of-line products.